Established in 1994 and located in Chehalis, Washington, Home Carpet Warehouse, Inc. has grown into Southwest Washington’s largest in-stock flooring dealer. Owner Jon Vigre worked with Chehalis Sheet Metal to install a Reznor R8HE-060-096 C-RTU. The newly installed unit conditions 30 pe The newly installed unit conditions 30 percent outside air and is responsible for keeping customers and staff comfortable by ventilating the airflow through the showroom to reduce strong carpet fumes.

Gas Condensing Rooftop Units

(C-RTUs) are an emerging high-efficiency technology in the commercial HVAC market.C-RTUs are particularly advantageous in applications with high outside air percentages and long run times as they are 10 to 20 percent efficient when compared to their non-condensing, gas-fired counterparts.

Ventilating Retail Showroom With High-Efficiency Units

Established in 1994 and located in Chehalis, Washington, Home Carpet Warehouse, Inc. has grown into Southwest Washington’s largest in-stock flooring dealer. Owner Jon Vigre worked with Chehalis Sheet Metal to install a Reznor R8HE-060-096 C-RTU. The newly installed unit conditions 30 percent outside air and is responsible for keeping customers and staff comfortable by ventilating the airflow through the showroom to reduce strong carpet fumes. The ventilation and heating function of the unit is gas fired with local utility service provided by Puget Sound Energy.

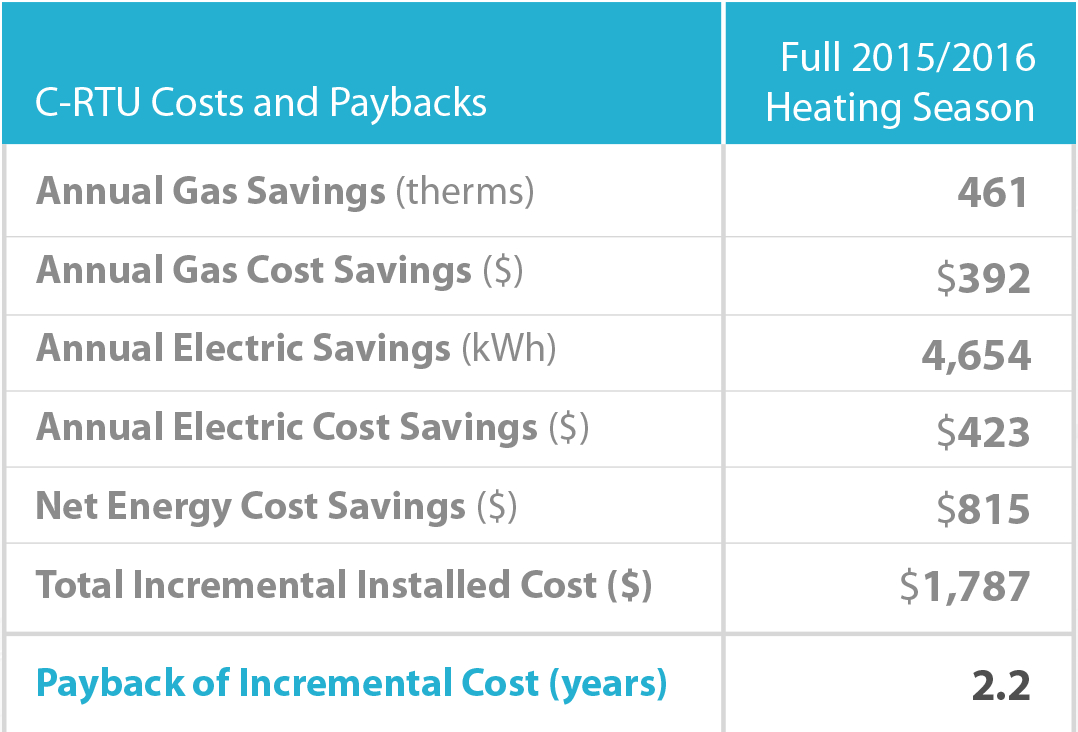

Since Chehalis, WA is in Climate Zone 4C, a relatively cold climate in the Pacific Northwest, this facility requires large heating loads for longer runtimes to compensate for the comparatively harsher climate. Applications with these characteristics – large heating loads and long heating runtimes – are ideal or C-RTU technology. Table 1 peels back the layers of savings and costs and highlights the relatively short payback associated with Home Carpet Warehouse’s C-RTU.

Saving Energy and Money

During the 2015/2016 heating season, the C-RTU helped the Home Carpet Warehouse save 461 therms of gas, 4,654 kWh of electricity, and $815 on their utility bill. Savings of this magnitude can significantly add to a building’s asset value by reducing its operating costs. In the Chehalis and Lewis County region, the average market cap rate was seven percent in 2016. This was used to estimate the increase to the building’s asset value by an approximately $11,640 due to its investment in C-RTU technology.

Thermal Efficiency Takes the Cake

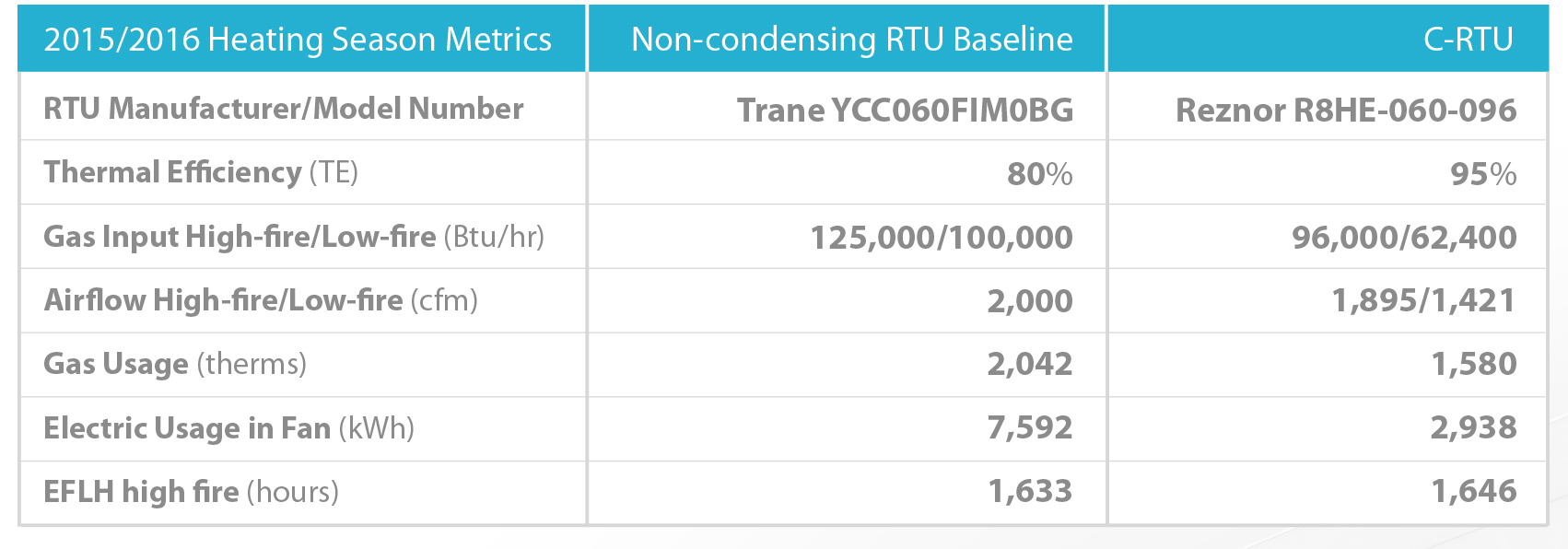

While non-condensing RTUs may operate at manageable thermal efficiencies such as 80 percent, the C-RTU installed at Home Carpet Warehouse outperformed its non-condensing counterpart significantly at 95 percent thermal efficiency, saving both on gas and electricity. Further, the field-measured combustion efficiency at the time of the original unit’s replacement had degraded down to 71 percent as RTUs, like any major building system, become less efficient over time. The additional savings realized by operating at the higher 95 percent efficiency made up for the added installation costs associated with the system required to properly dilute and dispose of the condensate.

Table 2 compares the performance of these two technologies side-by-side. At this site, the baseline non-condensing RTU had a two-stage burner and a single-speed blower. The condensing unit that replaced the baseline unit comes standard with a two-stage burner and a multi speed supply fan. Both the baseline and C-RTU thermostat fan controls were set to the “on” mode for continuous operation.

While replacing an existing rooftop unit is no small investment, Jon Bigre’s Home Carpet Warehouse managed to reclaim the incremental cost in just over two years and continues to enjoy substantial savings on utility expenses.