A Closer Look: Hydraulic Institute’s Circulator Pump Energy Rating Label

Circulator pumps operate in a range of methods and modes, meaning they can be configured to meet the needed pump head and flow for many applications. This flexibility of use makes it easier for installers to keep them on hand or in their service vehicles, install them, and complete the project. But how does an installer know which circulator pump is the right model for the project?

Like the Hydraulic Institute’s Commercial and Industrial Energy Rating Label (also known as the C&I Pump Label), the Circulator Pump Energy Rating Label is designed to assist those who use these products for new projects and/or retrofitting old pumps. Typical applications for the purchase and use of circulators include:

- Commercial and residential HVAC systems: boilers, air-handler units, and hydronic heating loops.

- Commercial and residential plumbing systems: pressure boosting, domestic water recirculation.

- Others: building owners, general contractors, facilities and plant managers, and application engineers.

Label Specifications

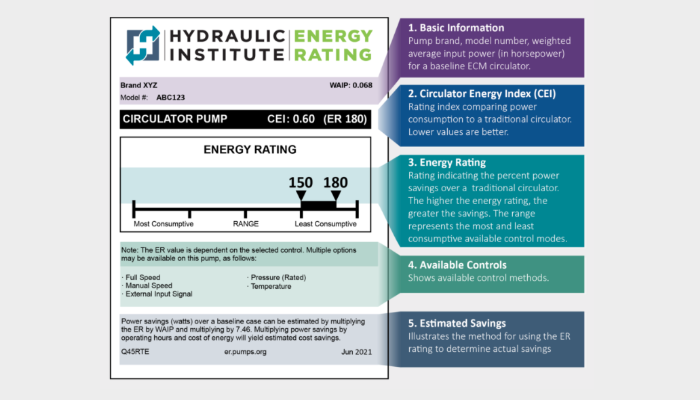

Although the Circulator Pump Energy Rating Label is similar in appearance to the original C&I Pump Label, it features different information relating specifically to the circulator. The most notable differences include:

- Circulator Energy Index is the comparison of how much power a specific circulator consumes compared to other circulators with similar features on the market.

- Energy Rating indicates the comparison of energy use between models but is listed as a range of numbers (e.g., 150–180). The range is significant because it reflects the different ways you can set up the onboard controls that come with the circulator. The higher the rating, the less consumptive the model, and the more energy savings users can achieve.

- Available Controls describes the options for using the pump such as temperature- or pressure-based operation and run-hours controls. The Energy Rating is directly linked to the selected control setting of the circulator.

- Estimated Savings is based on the calculation of the Energy Rating multiplied by the weighted average input power—a representation of the average input power needed to deliver a particular level of performance for circulators without controls—and multiplying again by 7.46 to convert horsepower of energy into watts of energy.

It is important to note the energy performance of a circulator is dependent on which control mode is set up for operation. When no controls are used, the circulator will often be in its most consumptive mode, reflected by the low end of the range. Using control modes such as pressure, temperature, and learning makes the circulator operate in a more efficient manner, which is represented by the high end of the range.

Why it Matters

When asked why the Circulator Pump Energy Rating label is significant, Hydraulic Institute/Pump Systems Matter manager of business development, Matt Derner, was clear. “With manufacturers designing more efficient pumps with integrated controls, the circulator Energy Rating label supports the industry’s push ahead of federal regulations. This helps ensure the marketplace is educated about the savings potential of smart pumps and drives transformation.”

How Products Receive the Label

The Circulator Pump Energy Rating Label was created from a collaboration between manufacturers, Hydraulic Institute, other energy organizations, and the Department of Energy. Circulator labeling is a voluntary process. To participate, manufacturers must sign up for the Hydraulic Institute Energy Rating Program, test their circulator models in a certified test lab, and subject their certified test labs to third-party auditing.

To learn more about circulator pumps and access helpful tools for calculating potential energy savings and monetary payback, visit Hydraulic Institute.