Energy Rating labels for commercial and industrial pump systems were created by the Hydraulic Institute in 2020 to foster an easier, streamlined way to determine the efficiency of a pump. Prior to the creation of the label, purchasers had to manually calculate efficiency based on multiple factors, which could lead to missed opportunities for improved energy performance and savings.

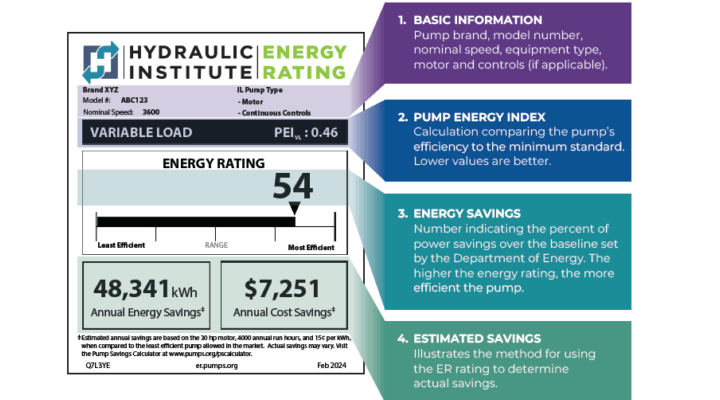

The label, also known as the Commercial & Industrial or C&I Pump Label, features numbers and measurements that indicate how much more efficient a specific pump is, compared to the federal baseline for pumps allowed to be sold in the United States. The primary feature of the label is the Energy Rating (ER) number. This number is derived from the Pump Energy Index—written as PEI on the label—a metric from the U.S. Department of Energy that is based on a uniform performance procedure all pump models are tested against.

This information is reflected in a numerical range from Most Consumptive to Least Consumptive. The higher the number, the less consumptive—or the more efficient—the pump. For example, a pump with an ER60 is 60% more efficient than the minimum required by law, or ER0. This number not only represents the lab-tested performance, but also allows you to calculate exact performance for your specific situation, based on pressure, flow, and run hours.

Even though the pump’s estimated annual savings is not provided, it can be calculated by using the information provided on the label, the net positive suction head required, run hours, and other features. Each of these elements are crucial to determine the pump’s function, operation, and savings.

Benefits of the C&I Pump Label

- Removes burden of calculation from purchasers.

- Allows purchasers and users to make a quick comparison to other pumps to aid the selection process. It is important to note the label is not a replacement for your overall pump selection process.

- Standardized lab testing means all models are subject to the same process, assuring users that ER results accurately reflect how pumps perform.

- Encourages further adoption of high-performance, high-efficiency pump technologies.

Why it Matters

Matt Derner, Hydraulic Institute/Pump Systems Matter manager of business development, explained the importance of this unique tool. The challenge, according to Derner, is getting pump specifiers to see the data and use it during their selection process. “Without this data, most specifiers will propose designs that simply meet the hydraulic requirements, based on the installation cost,” Derner noted.

“The label shifts the discussion to operating and lifetime costs, which can really change the framework for system owners. If a more efficient system costs a little extra but saves a lot more in terms of dollars and carbon/greenhouse gas emissions over its lifetime, a lot of owners will go for the more efficient unit,” he said.

How Products Receive the Label

Pump labeling is a voluntary process. To participate, manufacturers must sign up for the Hydraulic Institute Energy Rating Program, have their pump models lab tested, and subject their certified test labs to third-party auditing. To date, more than 13,000 C&I pump products feature the label. To learn more about commercial and industrial pumps and access helpful tools for calculating potential energy savings and monetary payback, visit Hydraulic Institute.

Additional Resources:

- Pump Power Energy and Cost Savings

- Commercial and Industrial Pumps (courtesy of Hydraulic Institute)