In order to keep buildings comfortable year-round, pumps circulate hot and chilled water in commercial hydronic systems. These pumps range from small in-line circulators to large pumps moving thousands of gallons per minute.

The cost of inefficient systems

Collectively, hydronic systems and pressure boosting pumps consume 10% of commercial building motor driven electricity. Many buildings run outdated pumps at full speed regardless of demand, leading to wasted energy, increased costs, and worn out components.

Smart pumps as the solution

Advanced systems integrate high-efficiency pumps and motors with built-in controls that adjust speed to

match real-time system needs. This ensures the right amount of flow and pressure. The result is significant energy savings, improved comfort, and reduced maintenance

- Integrated controls make it easy to program the sequence of operation and adapt to changing conditions.

- Variable flow control increases the lifespan of circulation pumps and piping.

- Building owners save energy and can monitor energy consumption data.

- Product manufacturers use standard pumps sizes and flange dimensions that simplify existing circulation pump replacement project

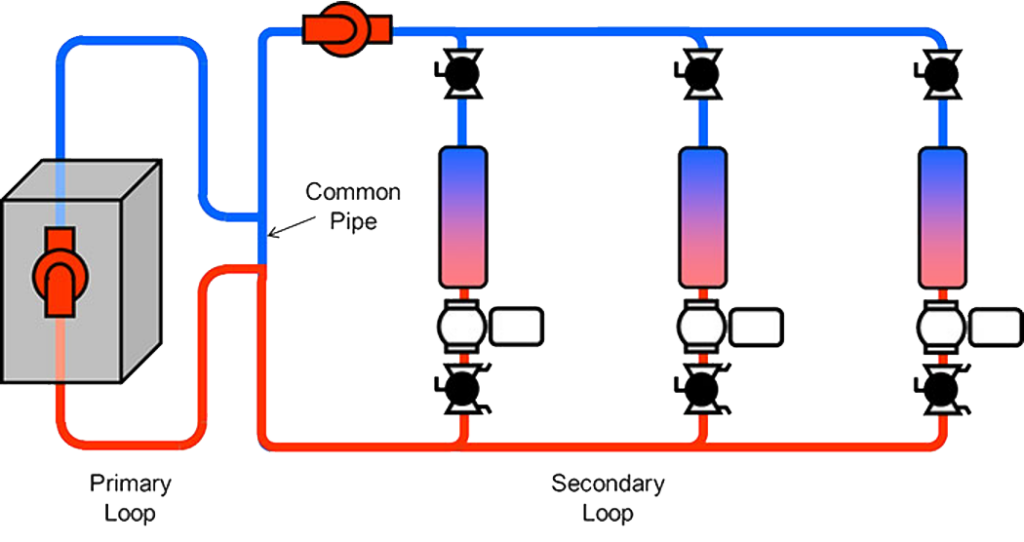

Sensorless pump control for primary and secondary loop (P-S configuration) optimization

Smart pumps bring embedded control logic directly into the hydronic system, enabling real-time adjustment of flow and pressure without the need for external sensors or complex building automation integration.

P-S configurations consist of two connected loops—the primary serving the thermal source and the secondary serving the distribution—linked by a common pipe that hydraulically decouples their flows

Primary loop

Enabling plant flow through real-time system monitoring and automatic output adjustment maintains optimal temperature differential and improves overall efficiency. No external sensors or complex programming required.

Secondary loop

Built-in intelligence continuously monitors pressure and demand, adjusting pump output to meet system demand.

P-S Configuration image courtesy of Hydraulic Institute for Pumps & Systems

Industry best practices

-

Select smart pumps with high energy ratings, built-in variable-speed drives, and advanced control capabilities to ensure efficient operation.

-

Choose pre-programmed control modes to maximize savings and simplify set-up for common hydronic systems.

-

Integrate with building automation systems (BAS) to enable coordinated control with central plant equipment for system-wide optimization.

-

Right-size pumps for actual load using accurate demand calculations. Oversized pumps reduce controllability and waste energy, while smart pumps adapt to installed conditions and maintain

necessary safety margins.

Smart pumps case studies

Class-A office building finds grade-A booster pump solution

Smart pumps help keep costs down at Providence Down Manor

Smart circulators provide convenience and savings for Bellwether Housing