A conversation with Derek Larson, senior associate engineer at McKinstry, and Jordan Pratt, energy engineer at Energy 350, on Washington State Energy Code, Clean Buildings Performance Standard legislation, and the potential of advanced performance dedicated outside air systems (DOAS)*.

Excerpted from the BUILDING HEROES podcast episode “VHE DOAS in Washington State.”

*Previously known as very high efficiency DOAS or VHE DOAS.

How has Washington State Energy Code changed over the past few years?

DL: Around the 2015 code cycle, Washington state started to implement certain things that we’re now seeing being expanded on and becoming standard practice. For the last seven or eight years, the Washington State Energy Code has been incorporating some aspects of DOAS systems, specifically the decoupling of ventilation air.

At that time, I remember it being perceived as a pretty big shift in what the expectations were. This wasn’t something anybody was really doing, and there was some pushback, people saying, “Well, this is going to make construction so expensive, how could we ever do this?” But now that it’s been in effect for many years, it’s accepted standard practice. With the current code, the big push is more and more toward heat pumps as our primary heating source, and it’s probably only going to get stricter.

What is the Clean Buildings Performance Standard legislation that has recently come into effect in Washington?

DL: The Clean Buildings Performance Standard, which was enacted as part of the Clean Buildings Expansion bill, is going into effect in 2026. The gist of it is that buildings above a certain square footage will be penalized if their energy use is above a certain target.

This is going to be normalized on a per-square-foot basis, so it will scale up and down with the building size. Compliance for larger buildings over 220,000 square feet will start in 2026, and smaller buildings will start complying at a later date. That’s going to put a lot more pressure on building owners to get their energy use in line with those targets.

They really need to start thinking about and making those changes today so when the compliance period starts, they’re already there. I think heat pumps and energy recovery ventilators (ERVs) specifically are going to play a very, very large role in getting the energy use down to those targets.

JP: As Derek mentioned, small to medium buildings won’t be required to comply for quite a while. With that being said, there are a huge number of commercial buildings in the area with an overall square footage of less than 25,000 square feet. And many of those buildings have packaged single-zone rooftop units, which are some of the least-efficient systems on the market.

So that is a building type that many utilities and regional efficiency organizations are fairly focused on. Even though the codes and standards are not going to affect those buildings, it’s still extremely important to improve their efficiency. These buildings are also typically harder to tackle because smaller businesses don’t necessarily have huge budgets.

What is a dedicated outdoor air system and what are its primary benefits?

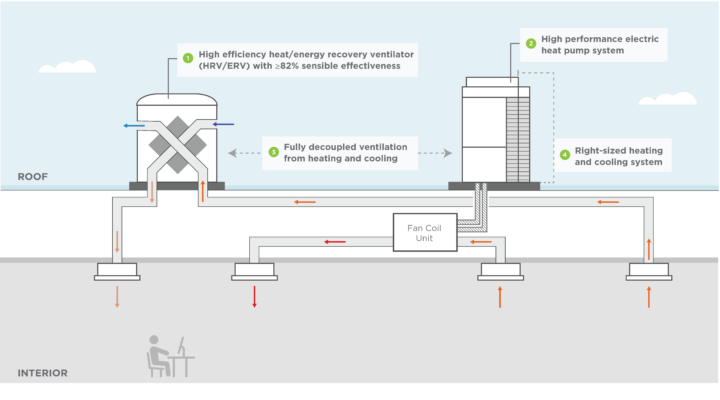

JP: DOAS is a commercial HVAC system that decouples or separates the ventilation from the primary heating and cooling system. Many traditional mixed-air systems like variable air volume (VAV) or packaged single-zone rooftop units combine the ventilation and primary heating and cooling systems.

One of the big benefits of a decoupled system is that these two critical functions can be flexibly controlled and optimized for energy efficiency. Due to DOAS providing 100% outside air independently of the heating and cooling system, it also provides excellent flexibility in extreme weather events and air quality conditions like wildfires.

Can you explain the advanced performance DOAS approach being researched and validated by the Northwest Energy Efficiency Alliance?

JP: The advanced performance DOAS approach is composed of four key concepts: 1) a fully decoupled ventilation and heating and cooling system, 2) a high-efficiency ERV with a minimum of 82% sensible recovery, 3) a high-performance variable capacity heat pump system, and 4) a right-sized heating and cooling system.

How does it elevate the traditional DOAS concept?

JP: The concept tends to focus on small to medium buildings. It works very well in office buildings, schools, retail, and other similar commercial applications.

This advanced performance approach improves on a typical DOAS by adding extremely high efficiency exhaust energy recovery to the ventilation system. So instead of exhausting warm, conditioned air out of the building, an ERV recaptures some of that heat through either a plate-style or a rotary wheel heat exchanger.

The advanced performance DOAS concept also utilizes the most efficient heat pump technology on the market to deliver heating and cooling functions with low energy. This solution has been proven to save on average 69% of HVAC energy use across more than a dozen demonstration projects over the last six years. We’ve also received feedback from building owners and occupants that DOAS delivers extremely high occupant thermal comfort and indoor air quality.

How does this compare to new code minimums?

JP: One key difference is Washington State Energy Code is required by law in certain applications. The advanced performance DOAS concept is more of a stretch performance set of guidelines.

In any new building or major renovation, Washington State Energy Code now requires a DOAS with 68% sensible recovery. The advanced performance DOAS concept shoots for a minimum of 82%, which is quite a bit more aggressive than the Washington code minimum.

Are there any concerns with equipment sizing? What do we do with redundancy to ensure continuous operation during maintenance or failure?

DL: Redundancy is present anytime we look at a heat pump type system, especially in Eastern Washington where some areas can get down to minus 20 degrees. Heat pump capacity is going to decrease as those outside air temperatures drop, which is exactly the opposite of what we want.

In climates where the weather is not as aggressively cold, like around the Seattle area where we design to only about a 20-degree outside air temperature, these heat pumps can theoretically thrive all year. Even during a freak weather event where you get a 5-or 10-degree day, you’ll still be OK.

JP: All HVAC solutions and design engineers need to figure out this challenge: what are we designing to? Are we OK with our systems being a little undersized in a major weather event, or is it a critical application and we have an entire backup system that can meet the load if one [unit] goes down?

These are economic decisions more so than just comfort situations. Based on what we’ve seen in the Northwest, these heat pump systems can do well—even in Idaho, Montana, and Climate Zone 6—when we start getting into the minus 20s.

With that said, it is often a good idea to have a backup solution but paying for the most efficient piece of equipment to have it meet your 50-year-event load is not the best economic decision, in my opinion. Having a little electric resistance backup or natural gas backup is an easy solution, and it makes a lot more sense when you’re sizing for a couple hours a year, or maybe even a few hours every 10 years.

Are there concerns about the installation and maintenance of DOAS?

DL: On the installation side, larger variable refrigerant flow (VRF) systems can be a little finicky. There are a lot of dos, don’ts, and things to watch for. It’s super critical to get a mechanical contractor who is trained on installing VRFs.

JP: We hear a lot of concerns from building facilities staff about high efficiency heat pump solutions. It has proprietary controls. It has refrigerant. It’s a complicated system. If they don’t have a technician who can work on these systems, maintenance can be a challenge.

Do you have any final points or things to consider?

JP: In the world of commercial HVAC, there is no onesize-fits-all solution. There is certainly not a perfect technology or system. Advanced performance DOAS is a good recipe to get really low energy use and have extremely high levels of thermal comfort and improved indoor air quality for occupants. Sometimes the best solution is a proven, straightforward HVAC system that’s been done over and over again and shown great results.