HVAC

Better comfort and energy costs start with the right HVAC. Understand how heating, cooling and airflow all directly contribute to the energy efficiency and tenant comfort of your commercial building.

Featured Downloads

All Rooftop Units (RTUs) Are Convenient, But Most Are Wasteful

Rooftop units (RTUs) supply heating and/or cooling to meet the thermal comfort requirements of commercial buildings. Inherently convenient, RTUs package heating, cooling and ventilation equipment together in a space that is accessible to technicians without taking up precious real estate. However, most RTUs are using much more energy than necessary. Efficient gas RTUs incorporate a combination of energy-saving features to reduce annual HVAC energy use by up to 40%.

learn moreUpcoming Event

Delivering High Performance Using Very High Efficiency DOAS Systems

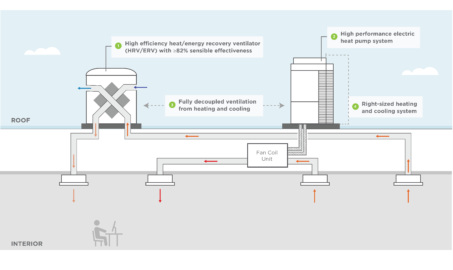

With the ever-increasing environmental impacts of local pollution, extreme weather events and wildfires, there is a necessity for resilient, flexible, and extremely efficient HVAC systems. A very high efficiency (VHE) approach to DOAS maximizes energy efficiency by decoupling ventilation air from comfort conditioning, including air-to-air heat recovery, right-sizing of a high efficiency heating and cooling system and minimizing fan power.

Featured Resources

Quick Jumps

-

Very High Efficiency Dedicated Outside Air Systems

The next step in the ongoing evolution of HVAC design, very high efficiency DOAS uses the most efficient HVAC equipment and key design principles to provide cleaner and safer indoor air, enhance indoor comfort, and reduce commercial building HVAC energy use by an average of 69% (when compared to a code-minimum system).

-

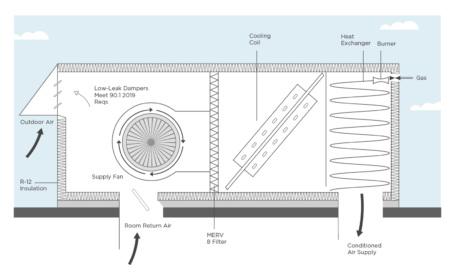

Efficient Gas Rooftop Units

Rooftop units (RTUs) supply heating and/or cooling to meet the thermal comfort requirements of commercial buildings. Inherently convenient, RTUs package heating, cooling and ventilation equipment together in a space that is accessible to technicians without taking up precious real estate. However, most RTUs are using much more energy than necessary. Efficient gas RTUs incorporate a combination of energy-saving features to reduce annual HVAC energy use by up to 40%.

![[Video] Very High Efficiency DOAS: How It Works and Why It Matters](/uploads/images/_453x270_crop_top-center_94_none/53656/vhedoas-explainervideo-thumbnail.jpg)